Machining

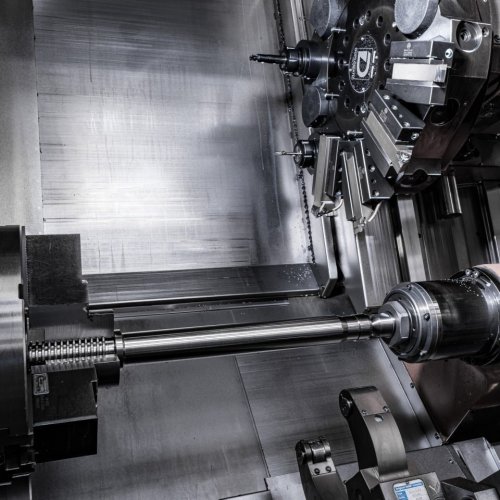

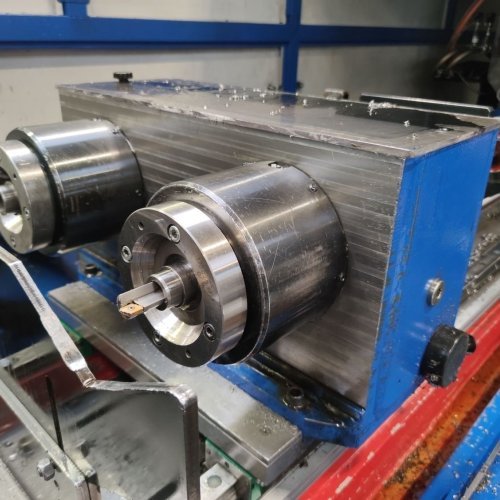

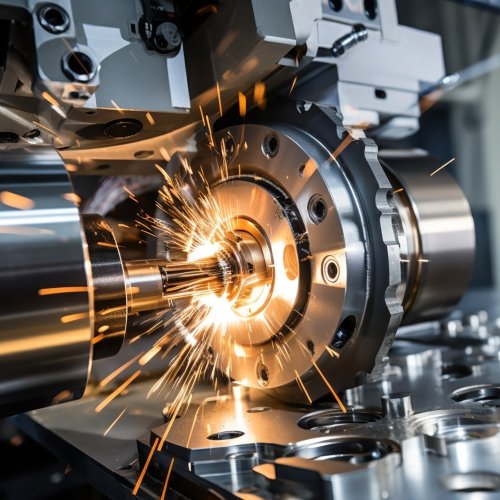

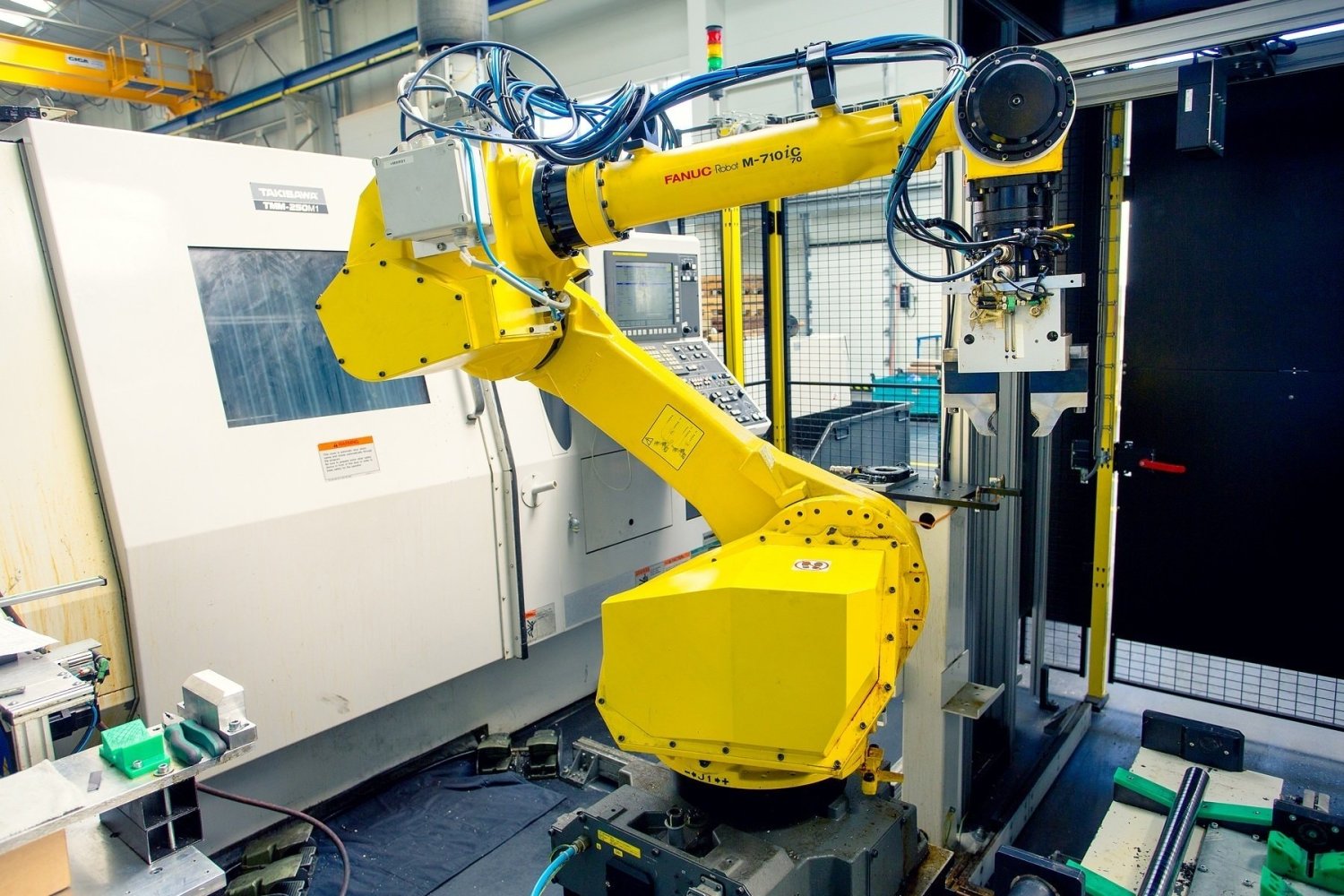

We deal with precision machining of common and special materials using progressive CNC technologies - turning, milling, grinding and drilling. We have both vertical and horizontal machining centers.

We use the most modern equipment in the industry for production, where regular investments are used to expand production and technological possibilities, modernization of current machinery and production facilities. All these steps are driven by the desire to offer our customers products, accompanied by the appropriate documentation according to their requirements for quality and deadlines.

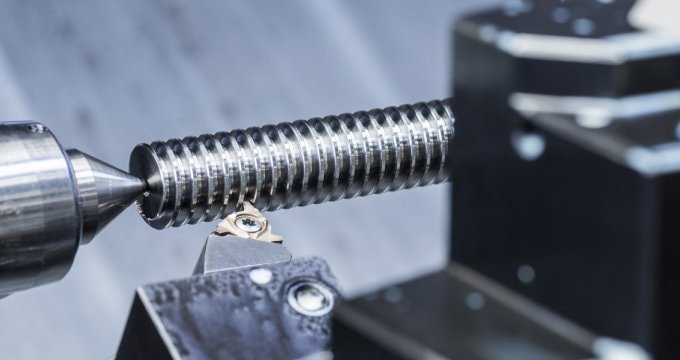

The manufactured parts are then inspected in our measuring laboratory, where, in addition to the measuring inspection, we carry out all non-destructive tests as well as material destructive tests. We work with special technologies such as thread rolling, deep drilling and diamond belt grinding to meet our customers' requirements.

Precision - Quality - Innovation

High precision machining

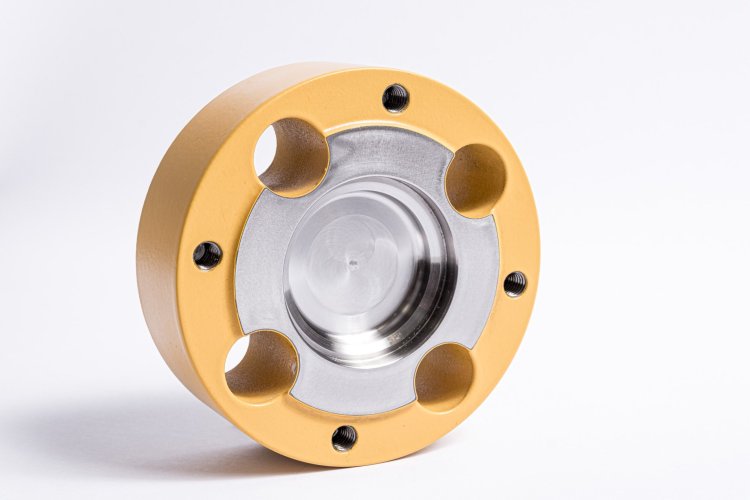

Our specialization is the production of precision parts in one-piece and small series.From single piece to thousands

You will supply the drawing documentation

We program the production

We produce

We prepare detailed documentation

Check

We will hand over the finished order to you

We provide machining of standard steels, stainless steels as well as special alloys with nickel content, such as Nimonic, Inconel, Hastelloy, etc., with which we have many years of experience. We are able to provide all common types of surface treatments and heat treatments for the parts we manufacture according to customer requirements. We cooperate with long-established suppliers.

Machined materials

Surface finishes

We are carefully prepared for your orders

High precision

Specialists in complex parts

High quality machinery

Machining up to 4 m

Expert know-how

Comprehensive quality assurance

Short delivery times

Maintaining technological development

Sanborn is equipped with a range of modern CNC machine tools covering a wide range of workpiece sizes and technological capabilities. Commonly machined part sizes range from 10x10mm to 4m long parts.

Modern machinery park

We produce for the following industries

We supply companies all over the world