Machinery

We are equipped with a range of modern CNC machine tools covering a wide range of workpiece sizes and technological possibilities. The sizes of commonly machined parts range from 10x10 mm to 4 m long parts. Machinery includes modern machines ranging from conventional CNC lathes and three-axis milling machines to high-end turning and milling centres and five-axis milling machines. Other technological capabilities of Sanborn include thread rolling with a maximum rolling force of 1200 kN and grinding including diamond belt grinding with a maximum workpiece length of 4 m.

Key machines

Hermle C62 U MT

- Five-axis continuous milling centre with full turning capability

- Work table with a diameter of 1 200 mm

- Table load capacity 2 500 kg

- Milling spindle with up to 70 kW of power and 560 Nm of torque

- High rigidity and precision for the most demanding applications

- High-pressure internal cooling up to 80 bar

Okuma Multus B750W 3000

- Five-axis turning and milling centre

- Comprehensive machining of highly demanding parts

- Lunette range from 75 to 430 mm

- Y-axis range ± 330 mm

- B axis with a range of - 30° + 210°

- Main spindle + counter spindle, turning/milling spindle 10,000 rpm

- Tool magazine for 80 tools

- Maximum workpiece diameter 600 mm, maximum workpiece length 3000 mm

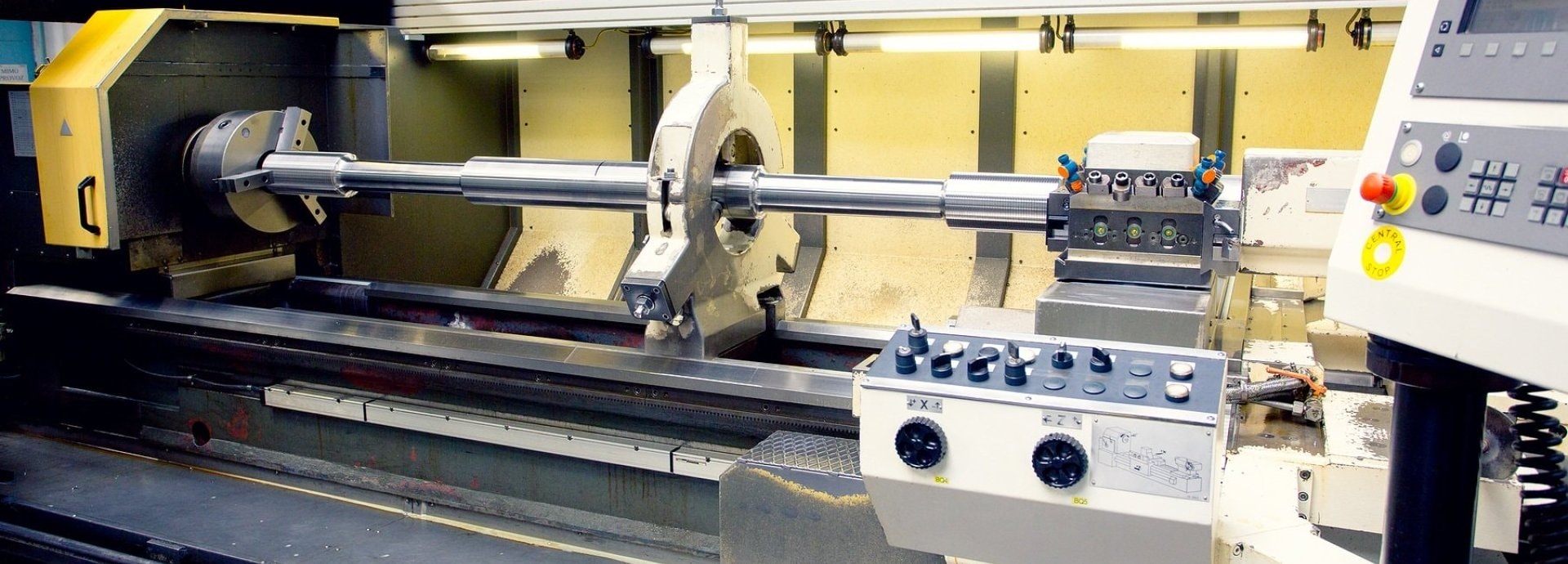

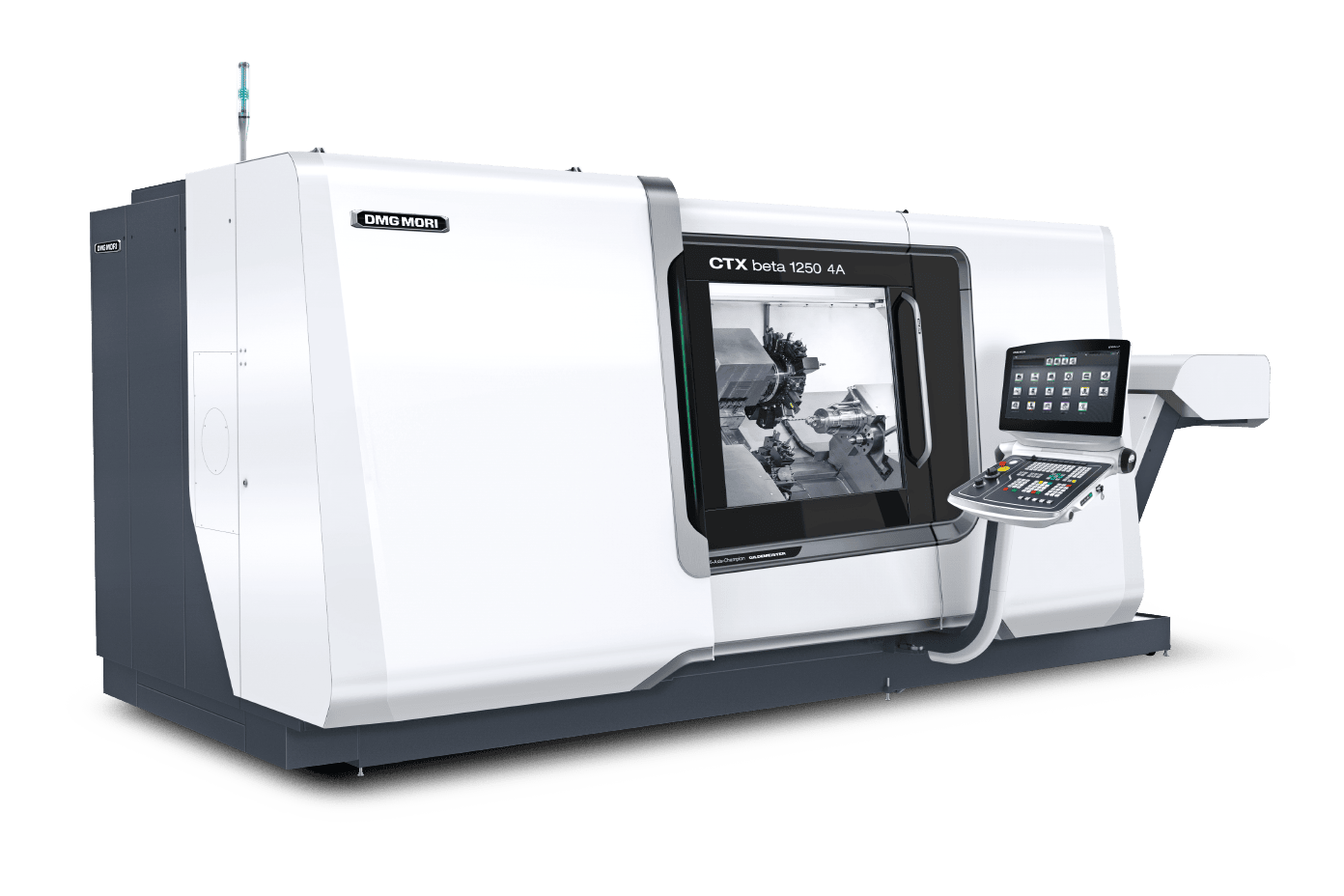

Two spindle turning centres

- Machines from leading European and Japanese manufacturers - DMG MORI, EMCO, TAKISAWA

- Single and double turret design

- Bar feeders for larger series of small parts or robotic arm for setting up cross-sections

- Driven tools and Y-axis for complex machining of parts in one step

- Lunettes for supporting longer workpieces and machining from the face

- Parts from 1 to 700 mm in length

Thread rollers

- 6 machines with a rolling force range of 25 to 120 t

- Rolling diameter range 6 to 180 mm

- Maximum workpiece length approx. 4,000 mm

- Thread rolling in materials up to a strength of 1,300 MPa

- Rolled thread profiles - metric, inch, rounded, trapezoidal and others according to customer requirements

Hardinge Super Precision T51

- Machining of parts mainly from hardened and otherwise hardened materials

- Driven tools for milling and drilling operations in high precision

- High dimensional accuracy and surface quality - replacing grinding

- Special one-piece bed for maximum rigidity and thermal stability

- Repeatable run-on position up to 0.0076 mm, workpiece roundness 0.005 mm

- Maximum workpiece dimensions ø250 mm and length 650 mm

Mazak Integrex

- Five-axis turning and milling centre for the production of precision and complex parts

- Integrated technologies to increase thermal stability and minimize vibration

- Two spindles for complete machining of the part in one operation

- Max. machined diameter 250 mm and workpiece length up to 300 mm

- High performance milling spindle enables full milling and drilling operations