Turning

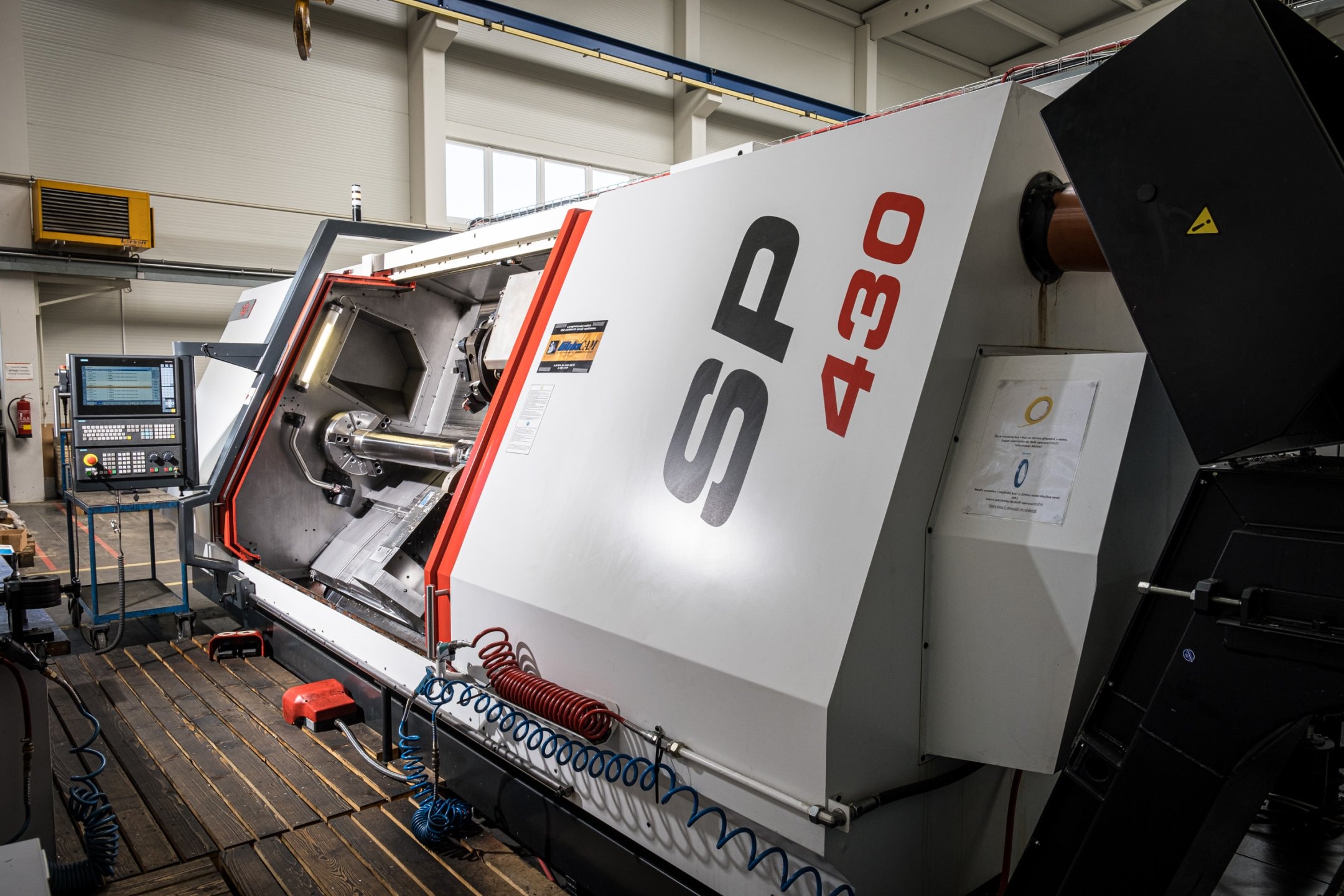

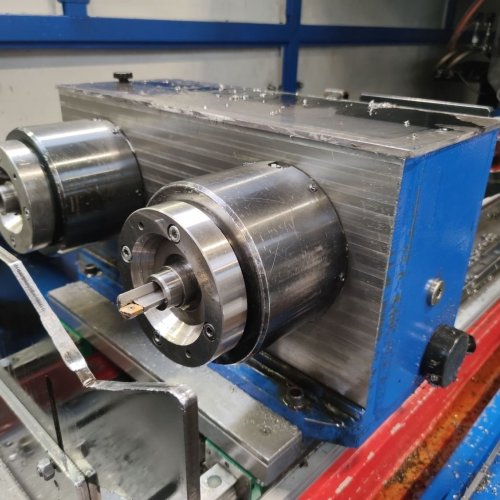

Turning is the core technology in our production, we have more than 50 CNC lathes.

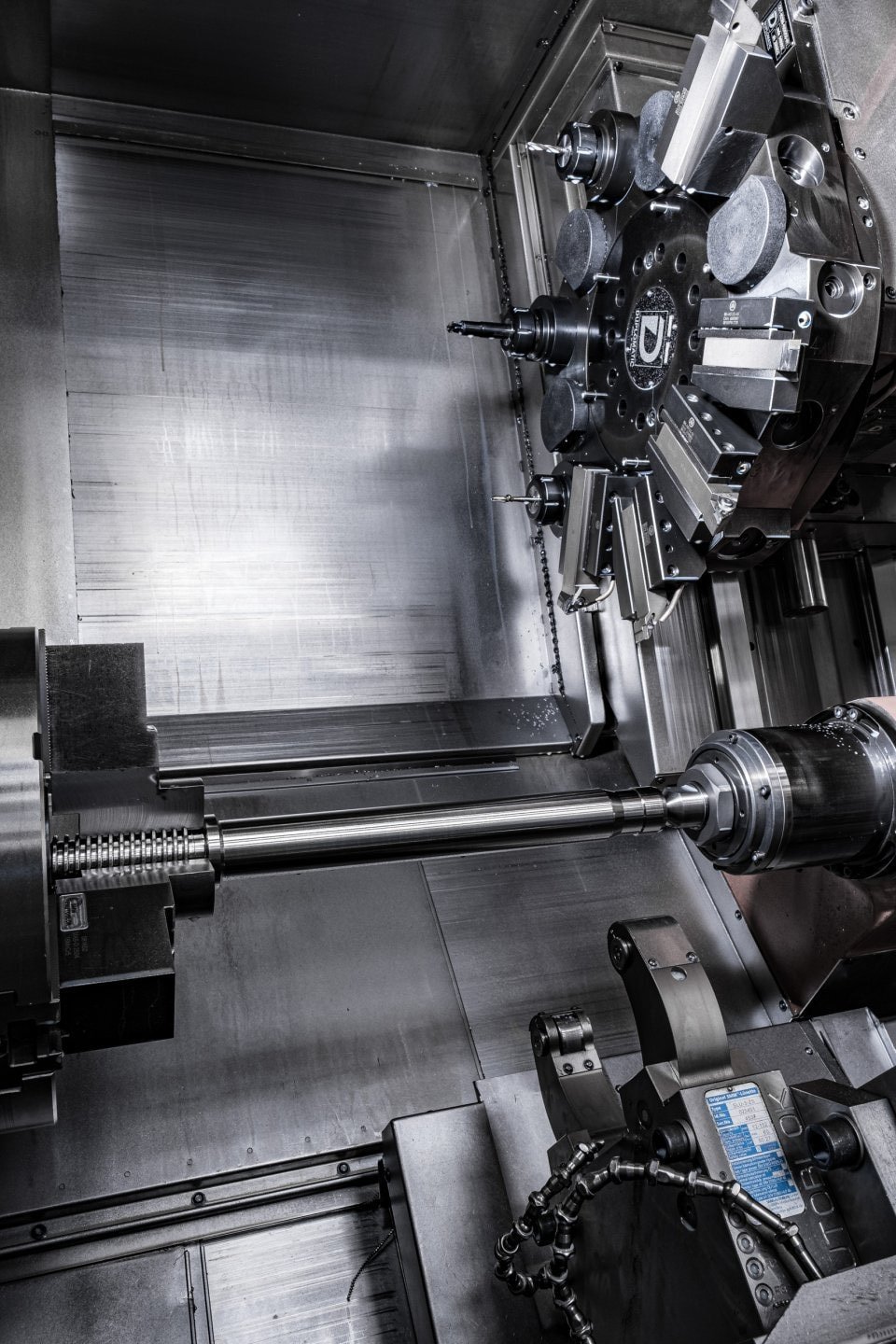

From simple two-axis machines to the most modern two spindle, two turret machines.

Our machine park also includes turning and milling machines for machining highly complex parts of various sizes.

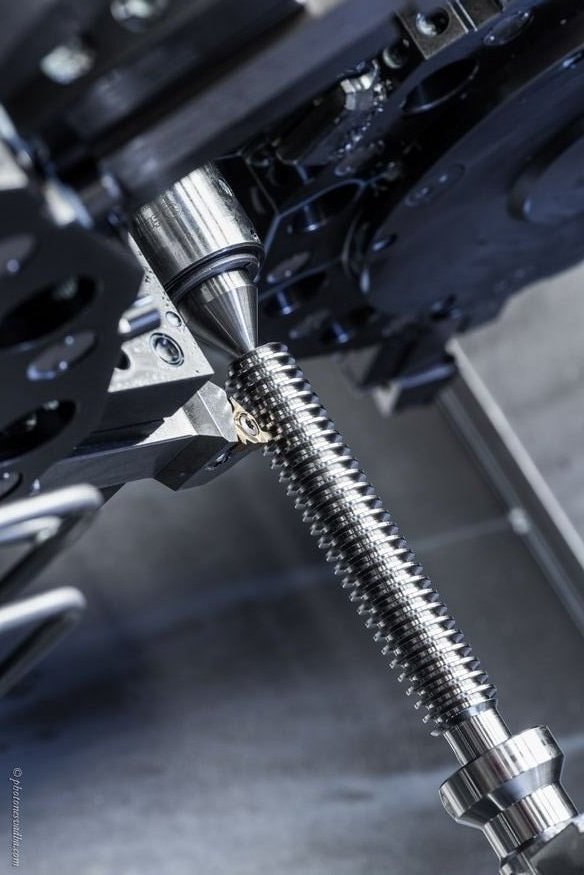

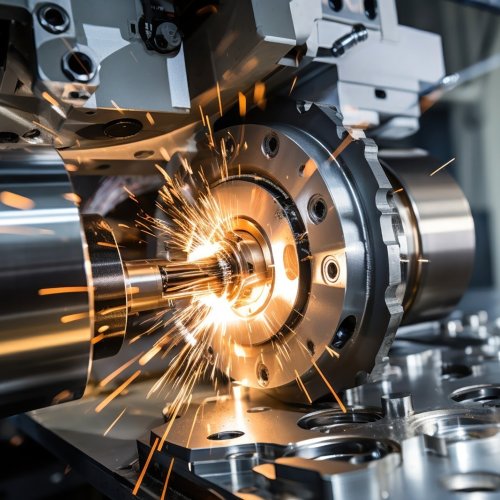

We also offer turning on very precise machines in air-conditioned conditions, where we can turn to an accuracy of 0.01 mm.

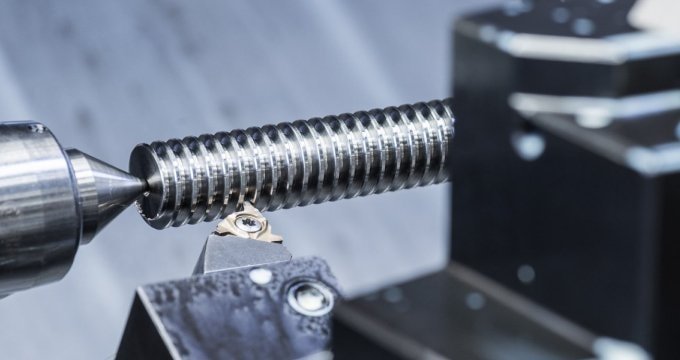

This technology is particularly suitable for materials that have been hardened or otherwise hardened and can replace grinding in many cases. Thanks to our extensive machine fleet, we can cover a really wide range of machined part sizes from a few millimetres to four metres.

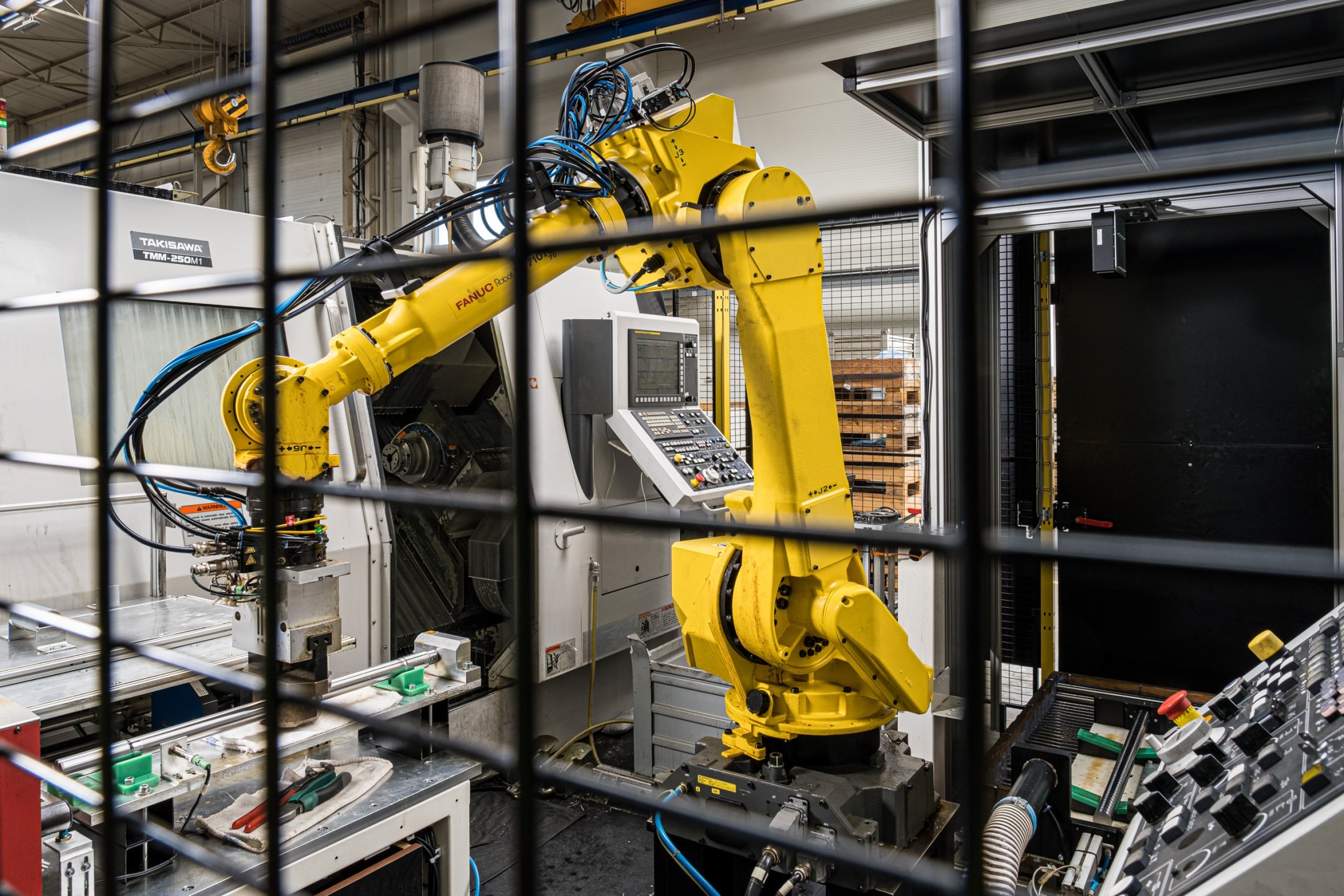

We can do all this in a wide range of materials from aluminium and other non-ferrous metals through various types of steel including stainless steel to heat resistant steels and nickel superalloys. We turn production batches from one piece to units of thousands of pieces. For larger batches, we have machines equipped with bar feeders or robotic stackers for production from cut or fired stock.

- Workpiece length: 5 - 5000 mm

- Workpiece diameter: 5 - 1 200 mm

- Max. workpiece weight: approx. 3 000 kg

Optimum number of pieces in a batch:

- up to approx. D100 x 700 mm 1 to 1,000 pieces

- up to approx. D400 x 1000 mm 1 to hundreds of pieces

- up to approx. D1 200 x 500 mm or D 600 x 5000 mm 1 to tens of pieces