Thread rolling

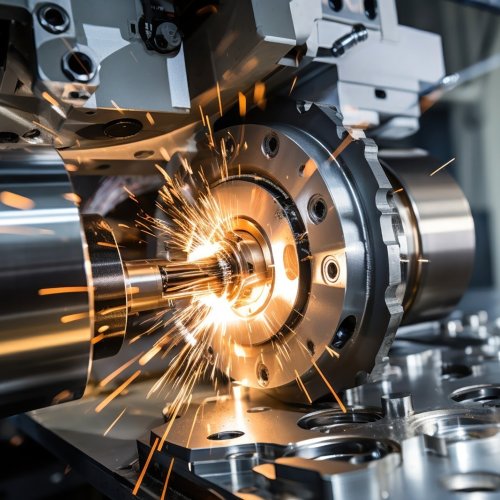

Thread rolling is a thread manufacturing technology in which the material is cold-formed to increase its strength. For this reason, it is the preferred thread manufacturing technology, especially for parts in critical applications where high mechanical or thermal loads are involved.

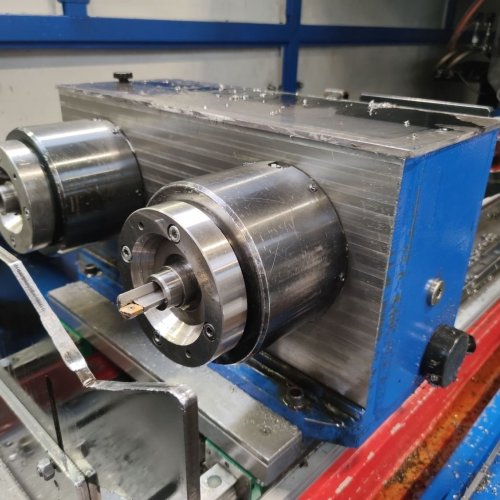

It is also a technology that is very productive for larger numbers of pieces in a batch. We have five thread rolling mills, the largest of which is one of the most powerful in Central Europe.

Our machines have a rolling force in the range of 250 to 1,200 kN or 25 to 120 tonnes. This enables us to roll thread from size M6 to approx. M180 depending on the mechanical properties of the material and the required thread pitch.

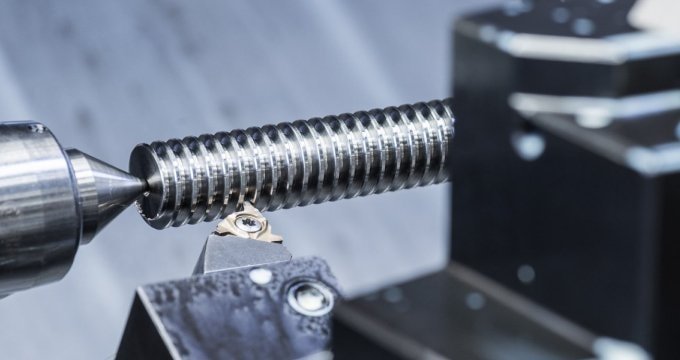

We usually roll threads up to a pitch of 6 mm. We are able to roll both metric threads and inch threads in various modifications. We can also roll trapezoidal, rounded or other threads according to customer requirements.

We are able to roll both in a notched manner, suitable for standard long threads up to approx. 250 mm, and in a continuous manner, where significantly longer threads on various threaded rods etc. can be rolled.

- Rolling force: 250 - 1200 kN (25 - 120 t)

- M6- M180 or similar size in inches

- Maximum workpiece length: approx. 4,000 mm